Pipeline Services

Protecting Your Pipeline

E&P Services Group offers pipeline services and pipeline protection programs. We provide technical field support on all projects, including NACE/AMPP Level I & II Senior Internal Corrosion Technologists.

What is Pig Sweep®?

The Pig Sweep® process is raising the bar for pipe cleaning services as well as allowing for the smooth flowing of oil and natural gas from the source to the refinery. Saving expensive and time-consuming testing and tailoring of your cleaning solutions

In the past, the technology required a sample of the pipe wall debris to be taken and a special chemical solution was created to address the specific contaminants. In many cases, more than one chemical cleaning run was needed, using multiple products to address each kind of unwanted debris and sludge. This resulted in additional time, money, lost production and often affecting dew point and odorant fade.

To address this, E&P has created the first nanoparticle mechanical cleaning process for oil and natural gas pipelines.

Pig Sweep Application Method

- Batch: injecting a large volume of chemical in a short period of time

- Continuous: injecting a consistent amount of chemical for continual cleaning

- Extended Batch: injecting a specific amount of chemical over a designated length of time

Pipeline Pigging

- Specifically designed for individual production systems

- Includes prep for I.LI. tool (smart pig), gauge plate, scraper

pig, foam cleaning pig etc. - Applications for piggable and non-piggable lines

- Pig Sweep (PS12) is a product specifically designed for the cleaning and removal of deposits within a dry gas line. This product does not interfere with mercaptan in sales lines. This product has a three fold purpose: cleaning, biocidal tendencies, and corrosion inhibition. (does not effect dew point)

Internal Corrosion Protection

E&P provides a corrosion inhibitor specifically designed for a known line segment, either gas or crude. After monitoring, we provide continuous injection or biocide batch treatment, depending on what is called for according to the flow regime.

Corrosion Monitoring

- For Regulated and Non-Regulated DOT lines including coupons, 3rd party lab MPY Data.

- Bacteria monitoring serial dilution, monthly bottles for SRB's and APB's

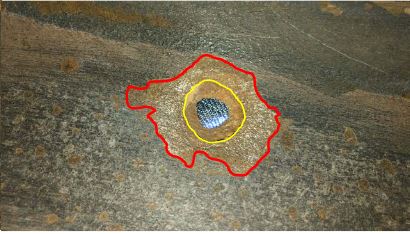

- Solid Analysis

- Provide assistance in DOT auditing.

- Highest level of priority on reporting consistent data to our customers to include in their DOT records

- Complete solids analysis (XRD / XRF)

- Corrosion Inhibiter

- Oil Soluble and Water Soluble Chemistries

- Proven independent lab tested with world class results

- Custom designed applications (continuous and batch treat)

References available upon request

Get Started Today